SERVICES

LASER CUTTING

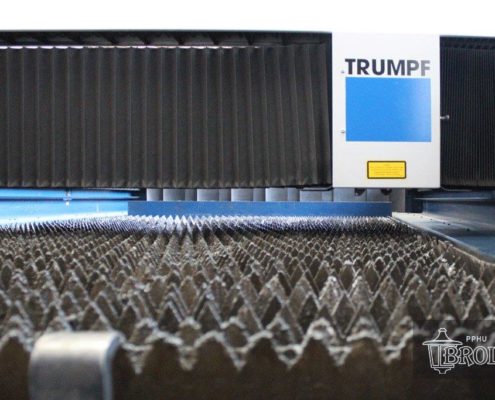

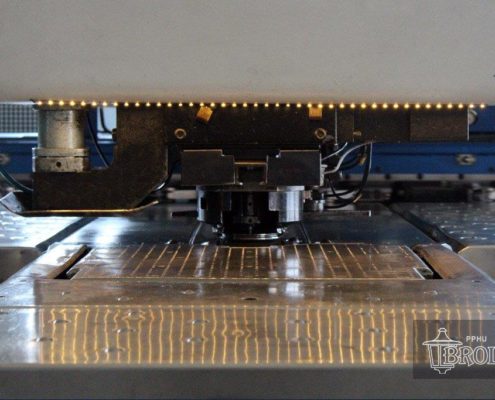

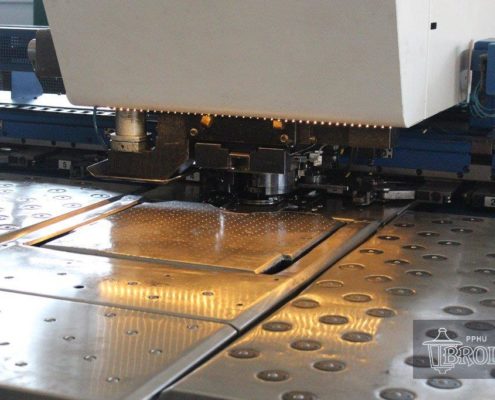

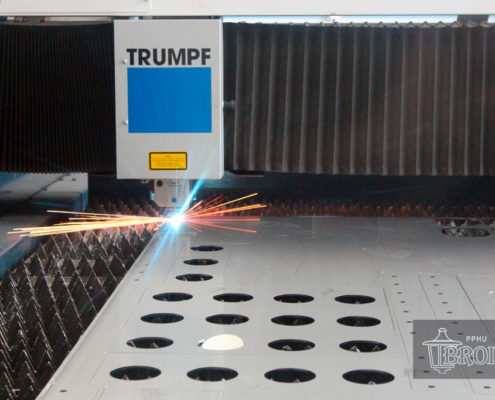

A new generation of trusty laser machines TruLaser L3030 will provide complex services in terms of laser treatment using modern technology.

The main purpose of laser cutter is cutting but the laser’s ray also allows to

- mark details for identification

- add central points of punching on materials

- treat metal sheets coated with foil

Max. thickness of sheet

16 mm (construction steel)

12 mm (stainless steel)

8 mm (aluminium)Our lasers are precise and reliable machines which make it possible to produce any ordered goods according to the sent specification.

SHEET METAL BENDING

We offer a possibility of bend sheets with the use of specialized devices.

We possess HGR squaring shears made by RICO to cut sweet metal with max. length of 3m and thickness of 6mm.

WELDING ELEMENTS

Welding processes are major manufacturing processes in our company.

Our firm has a certified system of Inner Production Control acc. to PN-EN 1090 which allows to issue declarations of conformities and confer the CE marks on steel construction with EXC2 class.

In the field of welding our company has implemented the EN-ISO 3834-2 system which confirms that BOLAM company has been controlled and declared as a firm carrying out welding works for load bearing steel constructions.

Welding services:

- construction black steel

- stainless steel

- aluminium

Welding methods:

- MIG (131) / MAG (135) consumable electrode welding with MIG (Metal Inert Gas) or MAG (Metal Active Gas).

- TIG (141) consumable electrode welding with Tungsten Inert Gas. This method allows to create high quality joints in carbon steel, stainless steel and alloy steel

In order to meet certain norms, we are obliged to constantly control the quality of welding joints.

MACHINING

We machine steel, aluminium and other construction materials.

WELDING DETAILS

Our company has ASPA ASM-713 and BSM 216 S1 welders to weld sheet metals with max. thickness of 2 mm.

SHEET METAL BENDING

It is possible to bend sheets up to 3000mm with the use of press brakes AMADA and HACO with the pressure of 1000kN and 600 kN. On short pieces we can bend sheet up to 12 mm.

CILING SHEET METAL

- Coiling length: max. 1500

- Coiling radius: min 120

- Sheet metal thickness: max. 2,5

COILING SHAPES

Possibility to bend steel and cold-bent shapes

SHEET METAL TREATMENT

We carry out technological operations on sheets such as: thermal drilling, countersinking holes, threading holes, welding mandrels, and injecting fasteners.

BENDING PIPES AND SHAPES

OTHERS

In cooperation we make powder and wet painting as well as galvanizing and hot dip galvanizing.